Special Cables

– Agree to start the trial orders

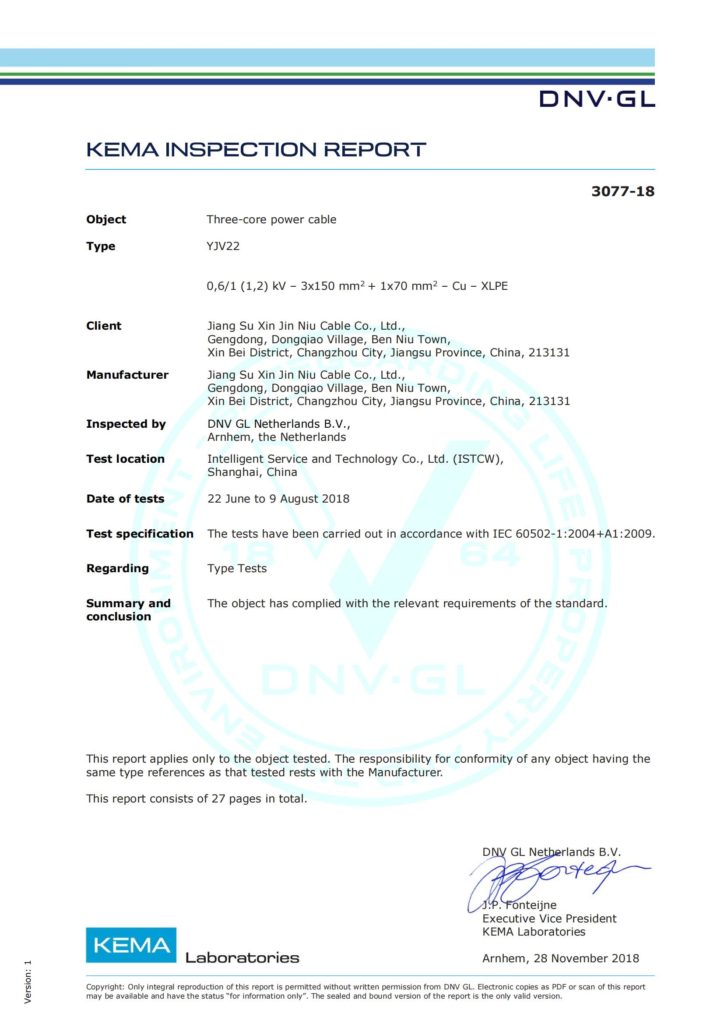

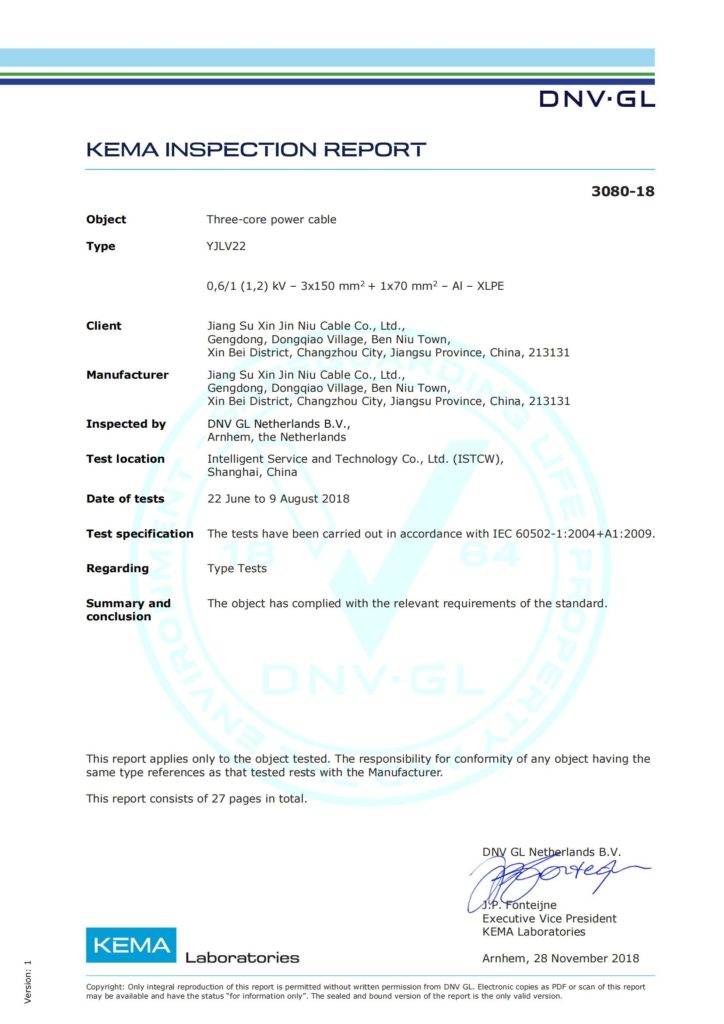

– Certified by 3C, CE, KEMA, SAA, TUV

– To ensure the continuity of your business by shortest date of delviery

– Diversified products portfolio strategy, so as to satisfy all your requirement

Product Categories

Special cable refers to a general term for a class of cables with special requirements or special occasions, such as high temperature resistance, fire resistance, acid and alkali resistance, wear resistance, oil resistance, radiation resistance, termite resistance, cold resistance and so on.

Fire-Resistant Fireproof Cable

Military Special Cable

High Temperature Resistant Cable

Special Cables For New Energy

Customized Services

We will provide our design plan according to your request. After you confirm it, then we will make a sample to confirm it. After the sample is confirmed, it will go into mass production.

- Application scenarios, running results

- Design solutions, product customization

- Customer confirmation, sample confirmation

- Without any questions, go into mass production

The Cable Factory

You Can Trust

We are a modern high-tech enterprise focusing on cable design, production and sales, and we are a key backbone enterprise here, focusing on the research, development, manufacturing and service of wire and cable products, going on providing the safe solution of cables.We have the most perfect manufacturing and equipment, we are one top of the cable industry, we would be the global leader in cable manufacturing industry.

Our Production And

Testing Equipment

We have advanced production equipment in domestic market, mainly produce power cables, control cables, high-grade home-decoration wires and cables, rubber wires and cables, overhead insulated cables, low-voltage wires and cables, medium and high-voltage wires and cables, etc., covering dozens of models and more than thousands of specifications. We are fully equipped with testing equipment to ensure the safety of every meter of wire and cable.

Certificate Qualification

Order Flow

And Delivery Time

We will reply you immediately on your inquiry.The quotation will be passed by our relative department(Marketing Dep./Sales Dep./Technology Dep./Accounting price Dep.). After contracting,the delivery date is generally 5-7days. The process without any mistake. Pricing accurately.Quick response.

Customer communication and consultation

Accounting price

Quotation

Contracting

Inspection of raw materials, processes and finished products

Customer confirmation

Mass production

Delivery

Why Choose Us

Since 1980 (42 years), WANSUN CHIN.BULL reduce costs for our customers during the innovating, and we focus on investing in R&D , so as we can provide the innovative solutions of wires and cables, to support that our customers will be the leader enterprise in the world, to improve our customers' competitiveness in the market,to build long-term business strategy together.

"One-step service" to provide the complete range of R&D

Efficient product development system

Rapid mass production

and implementation capabilities

FAQ

Q:What’s your company MOQ?

A:Our company has MOQ requirement, but we also accept small quantity.

Q:When I want customized products, how to do?

A:We have Equipped with professional equipment, technicians & skilled employees, OEM & customized service is welcome. Drawings / samples are required.

Q:Can you give warranty of your products?

A:Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.

Q:Where are you? Can I visit you?

A:Sure,welcome to you visit our factory at any time.

Q:How about the delivery time?

A:Within 5-7 days after we confirm you requirement.

Product Knowledge

What Is Special Cable?

Special cable refers to a general term for a class of cables with special requirements or special occasions, such as high temperature resistance, fire resistance, acid and alkali resistance, wear resistance, oil resistance, radiation resistance, termite resistance, cold resistance and so on.

Classification of special cables

01-Fire-resistant fireproof cable

Fire resistance means that it can maintain operation for a certain period of time under the condition of flame burning, that is, to maintain the integrity of the circuit. This type of cable has the ability to supply power for a certain period of time in the flame. Fire-resistant cables can be divided into two grades according to the national experimental standard (GB12666-99): NHA and NHB; in general product naming, NHA is usually represented by GNH, which is called high fire-resistant cable. NHB is expressed as NH in general refractory products. Fire-resistant cables can continue to work (transmit current and signals) in the event of a fire, and whether they are delayed or not is not included in the assessment. The flame-retardant cable stops working quickly when a fire occurs, and its function is to be flame-retardant and self-extinguishing without being affected. The fire-resistant cable maintains normal operation for 180 minutes in the flame burning of 750 ~ 800 ℃ Fire resistant cable is actually another type of fire resistant cable. It is made of copper as the conductive wire core, seamless copper tube as the sheath, and inorganic mineral magnesium oxide as the insulating material. Because the whole is composed of inorganic materials, the entire fireproof wire does not burn. Nor does it delay burning. And can withstand fire. The test shows that the wire is always running normally after burning in the flame of 800-900℃ for 2 hours, and it is still intact after burning for 30 minutes under the flame of 1000℃, and continues to operate normally. Generally, the normal working temperature is 250 ℃, which can operate relatively safely and reliably.

02-High temperature resistant cable

Long-term continuous working temperature of 125 degrees, 135 degrees, 150 degrees, 180 degrees, 200 degrees, 250 degrees and more than 250 degrees is called high temperature resistant wire and cable.

There Are Two Main Categories Of High Temperature Resistant Cables

Fluoroplastic wire and cable: one of polyperfluoroethylene propylene (FEP, commonly known as F46), polytetrafluoroethylene (PTFE), ethylene-tetrafluoroethylene copolymer (ETFE, commonly known as F40), and polyvinylidene fluoride (PVDF). Fluoroplastic cables mainly include: high temperature communication cables, high temperature resistant lead wires and installation wires, high temperature compensation wires and high temperature resistant power and control signal cables for industrial use, radiation resistant cables for atomic reactors and wires for rolling stock, etc.

Silicone rubber insulated wire and cable: Silicone rubber has good heat resistance. It commonly used silicone rubber for wires and cables is methyl ethylene silicone rubber, and the working temperature range is -60 ° C ~ 180 ° C. Silicone rubber has good bending function and low temperature function, and it is not easy to be damaged and cracked. These functions are not available in general high temperature cables. Therefore, silicone rubber cables have a wide application scale and are a bright spot of high temperature cables. Silicone rubber cables are used in high temperature mobile cables, flexible power cables, motor lead wires, and high temperature operating places in low temperature environments.

03-Military special cable

The military industry includes six subordinate fields: weapons, nuclear, aviation, aerospace, military electronics and ships. In addition to military electronics, the other five aspects require the use of various types of cables.

04-Special cables for new energy

The Main Categories Of Special Cables For New Energy Are As Follows

a) Charging post cable for new energy vehicles (EV)

The electric vehicle charging cable is used to connect the electric vehicle charging device and the charging infrastructure, so as to transmit power to the electric vehicle, and is equipped with a certain number of signal lines, control lines, power auxiliary lines, etc. to ensure accurate control and safe operation of the entire charging process. . Charging cables are generally used in charging stations, parking lots, hotels, communities, garages and other areas, and portable charging cables can be placed in the car.

Charging pile cables are divided into two main categories

AC charging cable Rated voltage 450/750 V Commonly known as "slow charging"

DC charging cable Rated voltage 1000V Commonly known as "fast charging"

b) Energy storage cables (ES) used in energy storage systems

All cables are used on the DC side of the battery energy storage system, connecting cells, battery packs, battery packs to junction boxes or power conversion systems as fixed wiring, or wiring that encounters limited bending during operation.

Common classifications are as follows

DC 0, 6kV unsheathed (4mm2 to 70mm2)

DC1,0kV sheathed (4mm2 to 240mm2)

DC 1, 5kV sheath (4mm2 to 240mm2)

Use environment code

Long-term outdoor .......................................P

Indoor ..........................................................L

Temporary outdoor ......................................W

c) Photovoltaic wire for photovoltaic power generation (PV)

Photovoltaic lines refer to the series cables between the photovoltaic modules on the DC side of the photovoltaic power generation system and the modules, the parallel cables between the strings and between the strings and the DC distribution box (combiner box), and the DC distribution box to fission. It can also be used as the cable between the fission device and the transmission grid for AC application.

Let's Raise Your Project To

The Next Level, Now !

After understanding the requirements, we will help you to provide a completely free catalog .

We usually reply your message within 6 bussiness hours.