How To Identify The Electrical Cable Size?

Electrical cables are usually used to transmit electricity to different places from one angle to the other. Therefore, to identify these electrical cable sizes, it is essential to understand that incompatible sizes of electrical cables can convey incompatible amounts of current.

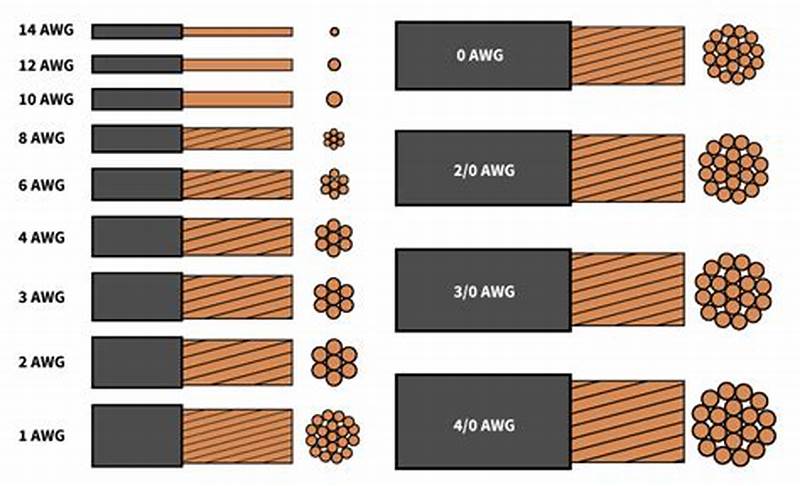

Also, the electrical cable is determined and measured in American Wire Gauge (AWG) and the International Electro-technical Commission (IEC) electrical wire standards. As a result, the larger or higher the AWG number becomes, the smaller or lower cable size is indicated. While for IEC, electrical cable standards enable easy operation of computers, workstations, printers, laptops, etc.

While identifying the right electrical cable size for lighting depending on their types, it’s not advisable to run too much current by way of too small of a cable because it can cause lasting impairment to the wiring. It’s also possible that it could start an electrical fire.

As luck would have it, there are a distinguished number of ways to identify the size of an electrical cable. These electrical cable and wire size methods only require essential appliances that are efficacious for indirect connections to all cables.

The following are the simplex methods or ways of identifying the electrical cable sizes:

- Firstly, please look at the cable insulators and their insulation.

- Afterward, explore for text or written digits on the insulation. This is done to check whether the last numbers in each string of text represent the AWG of the wires or not.

- Once you have confirmed that and find they are not, you continue to the next step, incising the wires with your wire cutter. But, it is good to note that the cut should stand up to the run of the wire.

- Make sure you measure the diameter of the cross-section in inches, of which the diameter is known to be the distance from one side of the cross-section to the opposite side in a straight line.

- Divide the diameters of the wires by 45.

- Determine the load of your suitable and fitting electrical cable size.

- Check the colors; supposedly, they should be black, red, white (neutral), and green in most cases.

- Examine and differentiate between cable sizes and understand their purposes depending on where one will use them.

2. What Electrical Cable Size Use?

Generally, one of the most commonly used electrical cable sizes is 12 and 14 gauges, consecutively, in residential, industrial, and different workplaces. Also, lots and lots of research has found that the larger appliances of electronics, such as electric stoves, electric heaters, water, dryers, and central air units, will often use 6, 8, or even ten gauges electrical wires.

But, the right size of electrical cable wire to use varies among different types of cable sizes. To understand or even select the right size of electrical cable, here are some types of electrical cable sizes that are useful and the ones that rely on our products:

Solar cable: These cables connect the components of a circuit and serve as a conduit where electricity travels. You have to mainly mount solar cable panels on the rooftop to avoid obstruction. The panels help the energy trespass to the current electrical cable size.

There are three types of solar cable, which enable and differentiate the classification of solar cables. Whereby the classification is done based on the numbers of wire gauges. Generally, these types are DC solar cables, DC main cables, and AC connection cables, either in modules or strings.

Electrical cable size itself: These electrical cable sizes have a significant role in transporting the energy power or electricity from one point to another. These cables are above local services; they are international ones.

Fire-resistant cable: This type of cable continues to operate in the presence of fire. They are good at testing the electrical cable size in earning different classifications. Typically, they work hand in hand with flame.

Besides that, fire-resistant are designed to maintain and retain the circuit and integrity of electrical cable size. Also, it continues to work for a specified period under defined conditions.

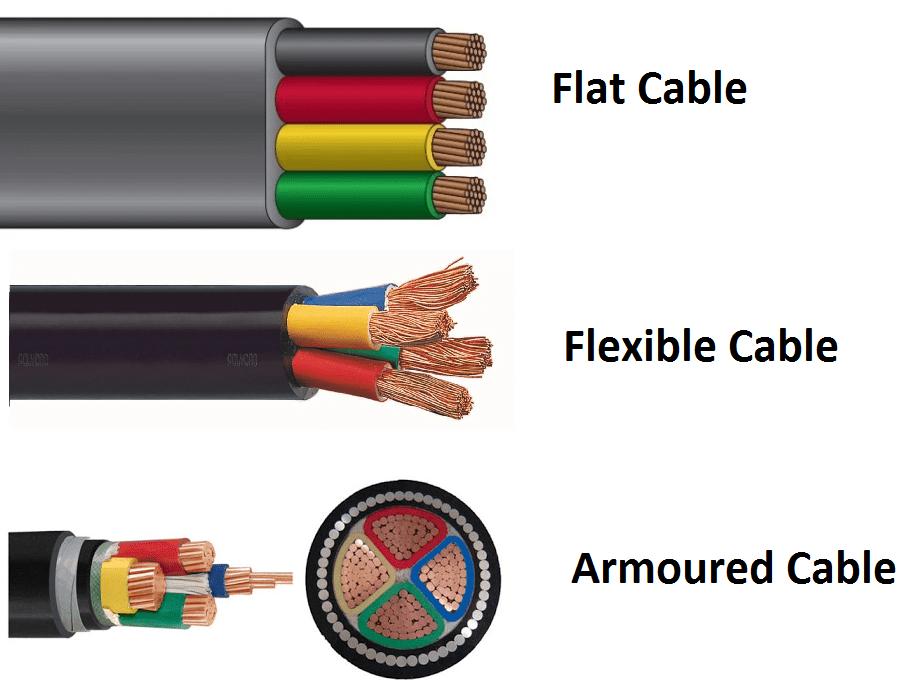

Armored cable is defined as a cable with a metal protective covering, making the best electrical cable size to use. Usually, these armored cables have hard-wearing power cables, which transfer and supply leading electricity.

Control cable: The control cable are famously known as multi-conductor cables, basically used in automation and instrumenting applications. They are in a UL relationship, where they are being measured purposefully to regulate the transmission of automated processes.

Typically, the control cables have a massive concern of flexibility when they are designed. This is because it is imperative to know if the control cable will require flexibility or you will continuously flex it. Also, control cable comes in 3 applications that do not limit against assembly lines, power distribution, and robotic.

All the above types of best electrical wires and cables have different sizes. That is where you will learn about the best sizes to use in each type of electrical cable. Additionally, the classification of electrical cables is also determined by numbers. Of which each number has a function. Other types include the low, medium, and high voltage cables, which are also helpful.

3. How Do You Measure The Electrical Cable Size?

The measurement of electrical cable size can be, at times, confusing and challenging. That is why you should always be attentive while sizing it because it’s vital to select the proper wire or cable size when measuring a wire for electrical installations. The wrong wire size for more oversized loads of current may create chaos and confuse coalitions, leading to the electrical equipment’s failure, hazardous fire, and serious injuries.

From that, it is good to make it clear that, from the scientific angle, all conductors, wires, and cables (apart from the superconducting ones) have some amount of resistance.

This resistance is usually straightly symmetrical to the length and the opposite symmetrical to the diameter of the conductor. This is because a voltage drop occurs in that conductor whenever current flows through a conductor. Usually, voltage drops may be abandoned for small lengths of conductors. Still, in the case of lower caliber and long-length conductors, we have to consider the considerable voltage drops for proper electrical wiring cable installation and subsequent load superintendence.

Besides that, when it comes to electrical wiring, cables, woofers, and speakers, among other electrical machines used for designing treasures, are all under the particular species subjects based on gauge. As a result, the proper electrical wire gauge for woofers and speakers is determined by their length and height and whether or not they are installed correctly in a wall.

Other than that, for you to have a secure and safe run of wire in perfection, you need to check its current with an electrical wiring gauge first and see if it’s of help and easy to handle. And remember, “wires for treasure makers are subject to physical stress factors.” In that case, to find the correct gauge for a particular project, use the prescribed tool.

There are five concrete and valuable steps that can guide you through conducting your measurement efficiently. They are as follows:

- The first thing to always do is eliminate the non-conveyor from electrical wiring and machine wires before sizing its diameter.

- With the help of a cutter rapier, wedge around the boundary of the insulation and let it lapse at its end.

- Measure both the non-metallic wiring and wire gauge using the sizing tools that specify measurements for these metals.

- Use the gauge beside the aperture to position the wire congenially without space. Gauge tools for nonferrous wires bear a different gauge scale than those for ferrous wires.

- Measure wires containing iron using the Standard Wire Gauge (SWG).

- Trap the short wires into the round caves.

4. What Is The Electrical Cable Size Chart Amp?

By assuming we all understand what a chart is, we, therefore, need to understand the term “amp.” An amp is an amperage, and it is referred to as the strength or energy of a current of electricity, which is determined and measured in amperes.

Also, the chart amp is the maximum current that a conductor can carry continuously under the conditions of utilization without exceeding its temperature rating. Note that you must use the correct size of electrical wire for the circuit’s current (load) requirement to prevent the wire from overheating.

Aside from that, ensure that the number and types of electrical gears are connected to a circuit to make it easier to examine the ampacity requirement of the conductor. Usually, a general-function house cable size circuit is designed for 20 amps. While a lighting circuit’s electrical cable may be designed for only 15 amps,

One of the known, easiest, and simplest methods for calculating chart amps is to take the wattages and divide them by the voltages. For instance, let’s take the watts of, say, a lighting fixture you are assigned to do or working for, as 100 and its volts as 20. With this, you’ll be required to divide 100 by 20, and you will get 5. Mathematically, this is how it should appear: 20/100 = 5.

With that done, just like any other job that requires tools, the electrical cable sizes also have tools that enable easy calculation of chart amps using tools like a multimeter. This tool is defined as a tiny hand-held gear that can measure resistance, voltage, and amperage.

It is always wise to remember that when planning or tasked with using this kind of tool, it’s vital for you to know what rating the specific model you are using has. A good example is when multimeters will be or are expected to be rated to handle a certain amount of current. If you use a multimeter rated for five amps, but you run 100 amps through it, then the multimeter’s fuse will be damaged.

Understanding and sizing the amp is imperative, especially when working on a lighting installation or electrical project. You will want to make sure the electrical wires used are not taking on more current than they can handle and are rated for.

In the example above, the electrical wiring cable size in the mechanism can only handle an electrical current of up to five amps. They are not supposed to carry more than that, based on the volts and watts being used. Before you carry out your work, always make sure you test all the wires in a light socket for an amp to know how much current it can handle before installing lights of specific wattage.

5. What Is The Length Of An Electrical Cable In Mm?

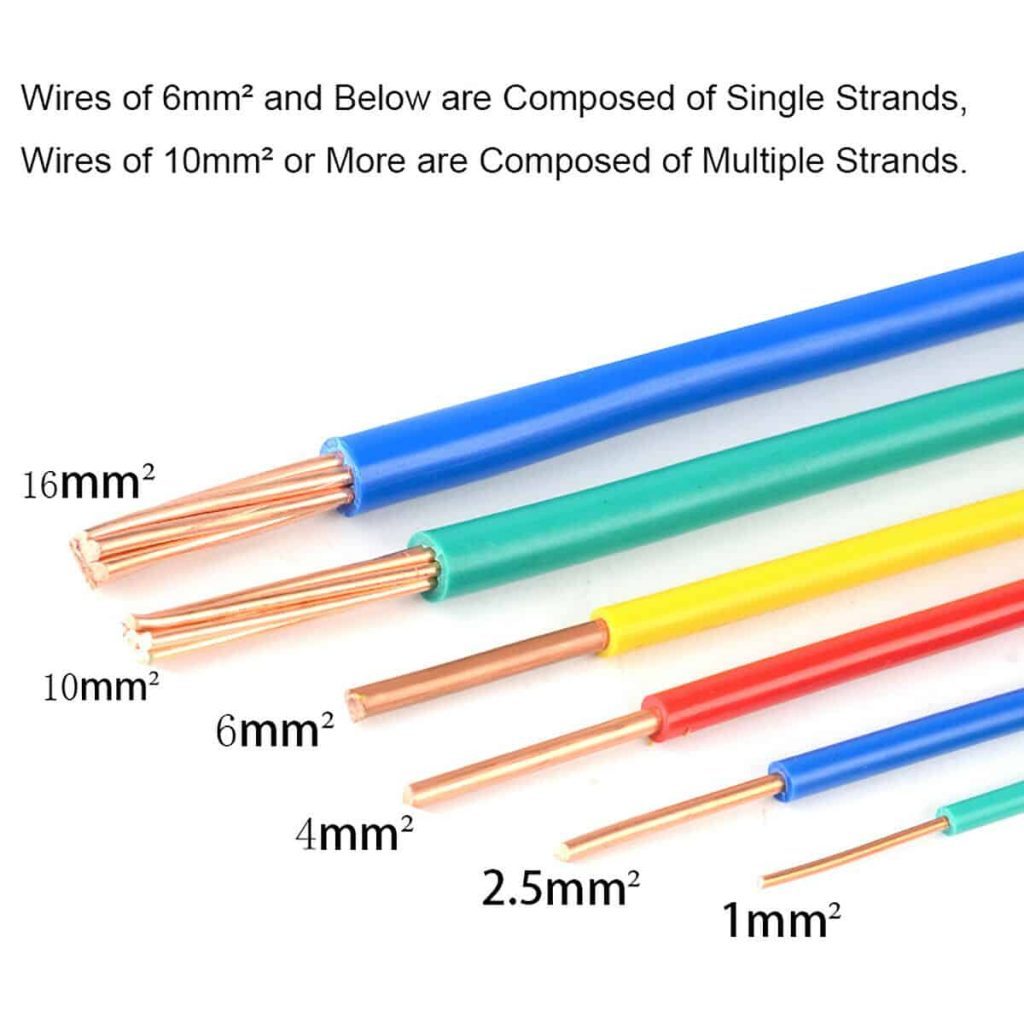

Mostly, when dealing with electrical cable size in mm2, you are likely to find what we call twin core and earth cabling used in every single place in different working places and homes in multiple varieties of sizes. Usually, 2.5 mm and 1-1.5 mm are the most commonly used micrometers for socket staff and lights.

In addition to that, there is another electrical cabling known as twin-core, which is used for internal and external electrical power cables. And as the name advocates, the twin is a formation of the other two navels, linked with the outer jacket and earth in between. With the inclusion of harmonized colors involved, the twin core cabling is also famously known to be made of a golden sheath for the live score and a blue arming for the neutral core. The earth core will be clear to see in green and yellow sheathing (but will become green when you install it). You then must cover it with an insulation sleeve adequately.